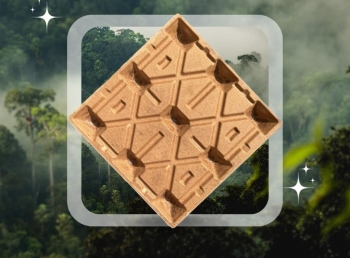

VinaTap Coconut Fiber Pallet Production Process

VinaTap coconut fiber pallets are produced using a modern, sustainable, and fully controlled process that meets global export requirements such as ISPM15 and Net Zero. They are an ideal green solution for international logistics.

1️⃣ Raw Material Collection

Coconut fiber is sourced from certified coconut-processing facilities in Vietnam. All input materials are selected for natural origin, consistent quality, and long-term environmental sustainability.

2️⃣ Raw Material Processing

The collected coir is cleaned, washed, and dried to remove dirt, sand, salt, and impurities — creating a hygienic and strong raw material base for pallet manufacturing.

3️⃣ Cutting & Fiber Preparation

The coconut fiber is cut and refined into specific sizes. Prepared fiber is fed into the production line, mixed, layered, and shaped before entering the high-pressure molding system.

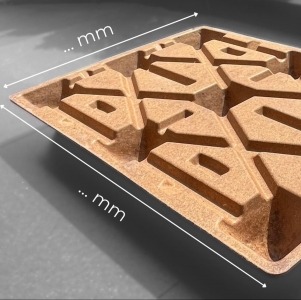

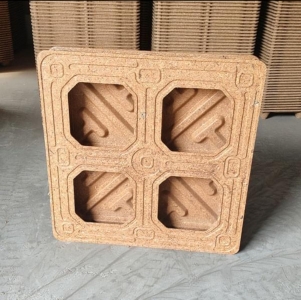

4️⃣ High-Pressure Pressing & Molding

Under controlled heat and hydraulic pressure, the material is compressed into rigid pallet structures. This step enhances strength, increases load capacity, and guarantees long-term durability.

5️⃣ Quality Inspection

Each pallet is inspected for:

- ✔ Structural strength

- ✔ Static & dynamic load capacity

- ✔ Moisture level

- ✔ Surface uniformity

- ✔ Dimensional accuracy

Only pallets meeting VinaTap’s export standards are approved for packaging.

6️⃣ Finishing & Packing

Pallets are trimmed, finished, stacked, wrapped, and packed according to export specifications for domestic and international transport.

Advantages of Coconut Fiber Pallets Compared to Other Pallets

1. Environmentally Friendly

Made from renewable coconut fiber, coir pallets reduce dependence on wood, plastic, and metal—significantly lowering environmental impact and plastic waste.

2. High Load-Bearing Strength

Coir pallets are strong, resistant to mold and rot, and perform well even in humid or high-moisture environments.

3. Cost-Effective

More economical than plastic pallets while maintaining durability and export-grade performance.

4. Lightweight & Easy to Transport

Lightweight structure reduces handling effort, improves workflow efficiency, and lowers logistics costs.

5. Natural Ventilation

Breathable fiber structure helps prevent moisture buildup inside stored goods, reducing spoilage.

Coconut Fiber Pallets Meet Net Zero & ISPM15 Standards

Net Zero Standard

Using recycled biomass reduces carbon emissions and supports global Net Zero initiatives. VinaTap’s production process minimizes waste and environmental impact.

ISPM15 Standard

Coir pallets comply with ISPM15:

- ✔ No fumigation required

- ✔ Pest-free & mold-free

- ✔ Export-ready for USA, EU, Australia, Japan, Korea…

Coconut Fiber Pallets for Export

VinaTap pallets are increasingly chosen by logistics companies, exporters, food factories, and green supply chains due to their stability, eco-friendly nature, and compliance with international regulations.

This strengthens Vietnam’s position as a leader in environmentally sustainable export materials.

Conclusion

VinaTap coconut fiber pallets are a durable, sustainable, export-ready solution for modern logistics. With strong load capacity, ISPM15 compliance, and competitive pricing, they are the ideal replacement for wooden, plastic, and metal pallets.

Email: vinatap@gmail.com

Website: www.vinatap.vn

WhatsApp / WeChat: +84 912 100 118