Coco Peat & Coco Husk Chip Production Process | Vinatap Vietnam

Vinatap Vietnam manufactures high-quality coco peat and coco husk chips using a clean, eco-friendly production process — washed, dried, heat-sterilized, and export-ready for global farms.

About Vinatap Vietnam

Vinatap Vietnam is one of the leading manufacturers and exporters of coco peat and coco husk chips in Southeast Asia.

With modern factories in Dong Nai and Ben Tre provinces, we specialize in producing low-EC, pathogen-free, high-performance coco coir substrates for hydroponics, horticulture, and professional agriculture.

Our facilities operate 24/7 with full automation — from crushing, washing, drying, to hydraulic compression — ensuring consistent quality and reliable export capacity to more than 20 countries worldwide.

1. Raw Material Selection

We source fresh coconut husks from the Mekong Delta region, known for its premium coconuts.

Each husk is carefully selected for fiber quality, texture, and moisture content to ensure a uniform, high-quality substrate base.

2. Crushing and Fiber Separation

The raw husks are fed into rotary crushing machines that separate:

-

Coco fiber (coir fiber) – used for ropes, mats, and industrial use.

-

Coco peat (coir dust) and husk chips – the main ingredients for growing media.

This stage defines the peat-to-chip ratio, which is later adjusted based on client needs (100% peat, 50/50 mix, etc.).

3. Washing & EC Reduction

The separated materials are thoroughly washed multiple times in large treatment tanks using clean water.

This removes salts, tannins, and organic acids, reducing the Electrical Conductivity (EC) to below 0.5 mS/cm, which is essential for hydroponic and greenhouse crops.

4. Dewatering Process

After washing, the material is passed through belt-press or screw-press machines to extract excess water.

Moisture is reduced to around 30–40%, preparing the material for energy-efficient drying.

5. Drying & Heat Sterilization

The semi-dried coco peat and husk chips are processed in rotary drum dryers powered by biomass furnaces (rice husk, cashew shell, or wood pellets).

Air temperatures reach 600–700°C, ensuring complete sterilization while lowering moisture to below 15%.

This guarantees clean, pathogen-free products ready for international shipping.

6. Screening & Grading

Once dried, materials are screened and graded by size:

-

Fine grade – seed germination, microgreens

-

Medium grade – hydroponic vegetables, berries

-

Coarse grade – orchids, landscaping, large root crops

Vinatap offers full customization according to crop type and buyer specification.

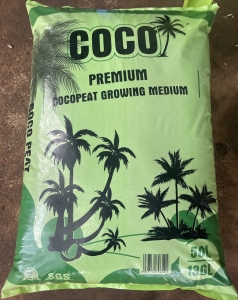

7. Compression & Packaging

The final materials are compressed using hydraulic presses into:

-

5 kg blocks

-

650 g bricks

-

Grow bags (100–120 cm)

-

Jumbo bags (6,000 L)

Each product is palletized, shrink-wrapped, and labeled for export under FOB or CIF Ho Chi Minh Port terms.

8. Quality Control & Certification

Every batch is laboratory-tested for:

-

EC (Electrical Conductivity)

-

pH (5.5 – 6.5)

-

Moisture content (<15%)

-

Microbial safety (no Salmonella, no E. coli)

We provide Phytosanitary Certificates, Certificates of Origin (CO), SGS or Intertek test reports, and OMRI documentation upon request.

Why Choose Vinatap Vietnam?

✅ ISO 9001:2015 Certified Manufacturer

✅ OMRI Listed for Organic Farming

✅ Low EC, High Porosity, Uniform Quality

✅ Large-scale 24/7 continuous operation

✅ Customized composition and private labeling

✅ Reliable export service to 20+ countries

Applications of Coco Peat & Husk Chips

-

Hydroponic and greenhouse cultivation

-

Horticultural nurseries and potting soil

-

Orchid and strawberry farming

-

Soil conditioning and organic composting

-

Eco-friendly landscaping

From Vietnam’s coconuts — to the world’s farms.

Contact Vinatap Vietnam

VINATAP Vietnam Co., Ltd

Long Binh Industrial Zone, Bien Hoa, Dong Nai, Vietnam

Email: vinatap@gmail.com

WhatsApp: +84 888 888 8609 | WeChat: +84 912 100 118

Website: www.vinatap.vn/en

coco peat production process, coco husk chip manufacturer Vietnam, coconut coir substrate, low EC cocopeat supplier, coir washing and drying process, hydroponic cocopeat, coco husk chip exporter, organic coco coir factory, Vietnam coco coir supplier, Vinatap cocopeat manufacturer

Online: 8

Online: 8

Total access: 4551341

Total access: 4551341