Vinatap Factory Tour – Inside Vietnam’s Leading Coco Coir Production Plant

Take a tour inside Vietnam Vinatap Company’s coco coir factory – a world-class facility producing organic coco peat, husk chips, and grow bags for export to 30+ countries.

Vinatap Factory Tour – Inside Vietnam’s Leading Coco Coir Production Plant

Discover How Vietnam Vinatap Company Produces World-Class Coco Peat & Grow Bags

Meta Description:

Take a tour inside Vietnam Vinatap Company’s coco coir factory – a world-class facility producing organic coco peat, husk chips, and grow bags for export to 30+ countries.

????

Welcome to Vietnam Vinatap Company

Located in Long Binh Industrial Zone, Bien Hoa, Dong Nai, Vietnam Vinatap Company is one of Vietnam’s most advanced and largest-scale coco coir processing factories, supplying premium coco peat, husk chips, and grow bags to farms and distributors across the world.

From raw coconut husks to ready-to-ship pallets, every stage of production follows strict ISO 9001:2015 standards and OMRI organic certification.

???? Where coconut waste becomes the world’s favorite growing medium.

????

1. Factory Overview – Scale & Capacity

Our production facility covers 2,500 square meters, including:

-

???? Raw Material Yard: capacity 1,000 tons of coconut husk.

-

???? Washing & Drying Area: 1,800,000 kcal/h biomass furnace, powered by rice husk & cashew shell.

-

⚙️ Mechanical Workshop: in-house fabrication of press, conveyors, and dryers.

-

???? Compression & Packing Zone: 5 fully automatic hydraulic presses for 5kg blocks & grow bags.

-

???? Warehouse & Logistics Hub: 1,000m² of finished goods storage, 24/7 loading system for export.

Production Capacity:

-

120 tons/day of processed coco coir substrates.

-

8,000+ 5kg blocks/day or 18,000 grow bags/day.

-

Continuous operation 24/7 to meet export deadlines.

????️

2. Modern Production Line by Vietnam Vinatap Company

The Vinatap factory uses integrated, automated lines developed by our own engineers for energy efficiency and quality consistency:

Step 1 – Coconut Husk Sourcing

We source fresh, mature coconut husks from Bến Tre and Mekong Delta provinces — known for the highest fiber density.

Step 2 – Crushing & Screening

Husks are shredded and screened into peat powder, husk chips, and fibers for each substrate type.

Step 3 – Washing & Buffering

All coco materials are triple-washed with clean water and neutralized using calcium to lower EC below 0.5 mS/cm.

Step 4 – Drying & Moisture Control

Material is sun-dried and then kiln-dried using a biomass furnace (700°C) to achieve moisture <15%.

Step 5 – Mixing & Formulation

Based on customer specifications, Vinatap blends:

-

100% coco peat

-

Coco peat + husk chips

-

Coco peat + perlite mix

Each ratio is mixed by automated screw conveyors for perfect consistency.

Step 6 – Compression & Packaging

Materials are pressed into:

-

5kg blocks (30×30×15 cm)

-

25kg bales

-

Grow bags (100–120 cm)

All wrapped in UV-protected PE plastic and palletized for export.

Step 7 – Final Inspection & Export

Each batch is tested in-lab, labeled with a QR batch code, and inspected before loading into containers for shipment.

???? Every bag, block, and bale that leaves Vinatap carries its own traceable origin.

????

3. In-House Quality Control Laboratory

Inside the factory, Vietnam Vinatap Company operates a dedicated testing lab to ensure each batch meets export standards.

We measure:

-

EC and pH levels (digital conductivity meter)

-

Moisture content (oven drying method)

-

Particle size distribution (sieving test)

-

Organic matter and carbon content

All data is logged and linked to the production batch, ensuring full traceability and consistent quality for every shipment.

????

4. Sustainability & Eco-Friendly Energy System

Our factory runs on 100% renewable biomass energy, powered by rice husk and cashew shell pellets.

This system reduces carbon emissions by over 70% compared to diesel heating.

We also:

-

Reuse washing water in a closed-loop system.

-

Convert coconut shell waste into biochar and fertilizer.

-

Promote zero-waste production principles.

???? Sustainability is not a slogan – it’s Vinatap’s production foundation.

????

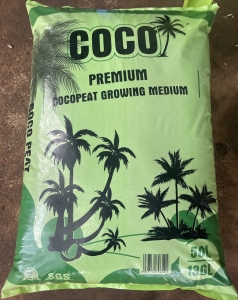

5. Products Made at Vinatap Factory

The Vietnam Vinatap Company factory produces a wide range of coco coir substrates:

|

Product Type |

Description |

Packaging |

|---|---|---|

|

Coco Peat Block (5kg) |

Washed, low EC, pH-balanced substrate |

Shrink-wrapped / pallet |

|

Coco Husk Chip Block |

High drainage media for fruit crops |

5kg block / 25kg bale |

|

Premium Mix Grow Bag |

Peat + husk + perlite for hydroponics |

100×15×15 cm / 100×20×15 cm |

|

Hydroponic Slab Bag |

For strawberries, tomatoes, and melons |

UV PE plastic with holes |

|

Organic Loose Peat |

OMRI-listed coir for soil blending |

150L bags or bulk |

????

6. Export Markets & Global Partners

We export to Australia, Japan, Korea, New Zealand, Poland, Germany, the USA, and Canada, supplying:

-

Importers & wholesalers of horticultural media

-

Greenhouse farms and hydroponic growers

-

Organic certification programs and distributors

Vinatap products meet all import regulations:

BICON (Australia), MPI (New Zealand), EU Plant Health, and USDA APHIS standards.

????

7. Why Visit the Vietnam Vinatap Company Factory

✅ See modern, clean production lines in operation.

✅ Understand strict quality control systems.

✅ Discuss OEM / Private Label cooperation directly.

✅ Experience real-time compression and testing process.

✅ Build trust and transparency with your supply partner.

???? We welcome visitors from all over the world to witness Vietnam’s leading coco coir production facility.

????

Did You Know?

Did you know that Vietnam Vinatap Company can produce and load a full 40HQ container of coco peat blocks in just 12 hours?

Our synchronized production system and in-house logistics make us one of the fastest, most reliable suppliers in Asia — without compromising quality.

???? Speed, sustainability, and quality – all in one factory.

????

Visit & Contact Vietnam Vinatap Company

Vietnam Vinatap Company (Vinatap Co., Ltd)

???? Long Binh Industrial Zone, Bien Hoa, Dong Nai, Vietnam

???? Email: vinatap@gmail.com

???? WhatsApp: +84 888 888 8609 | WeChat: +84 912 100 118

???? Website: www.vinatap.vn

???? Factory visits available upon request (for importers & distributors).

????

SEO Keywords (Optimized for 2025)

coco coir factory Vietnam, coco peat manufacturer Vietnam Vinatap Company, coco coir production plant, coco peat export factory, grow bag manufacturer Vietnam, OMRI coco peat factory, hydroponic substrate factory, organic coir supplier Vietnam, coco husk chip factory, visit Vinatap factory, Vietnam coco coir exporter, sustainable coir production, Vietnam coir grow media

Online: 5

Online: 5

Total access: 4551345

Total access: 4551345